At SIENN, we believe technology should support you

It should free you from spending hours in Excel so you can focus on quality, craftsmanship, creativity — the work that really matters.

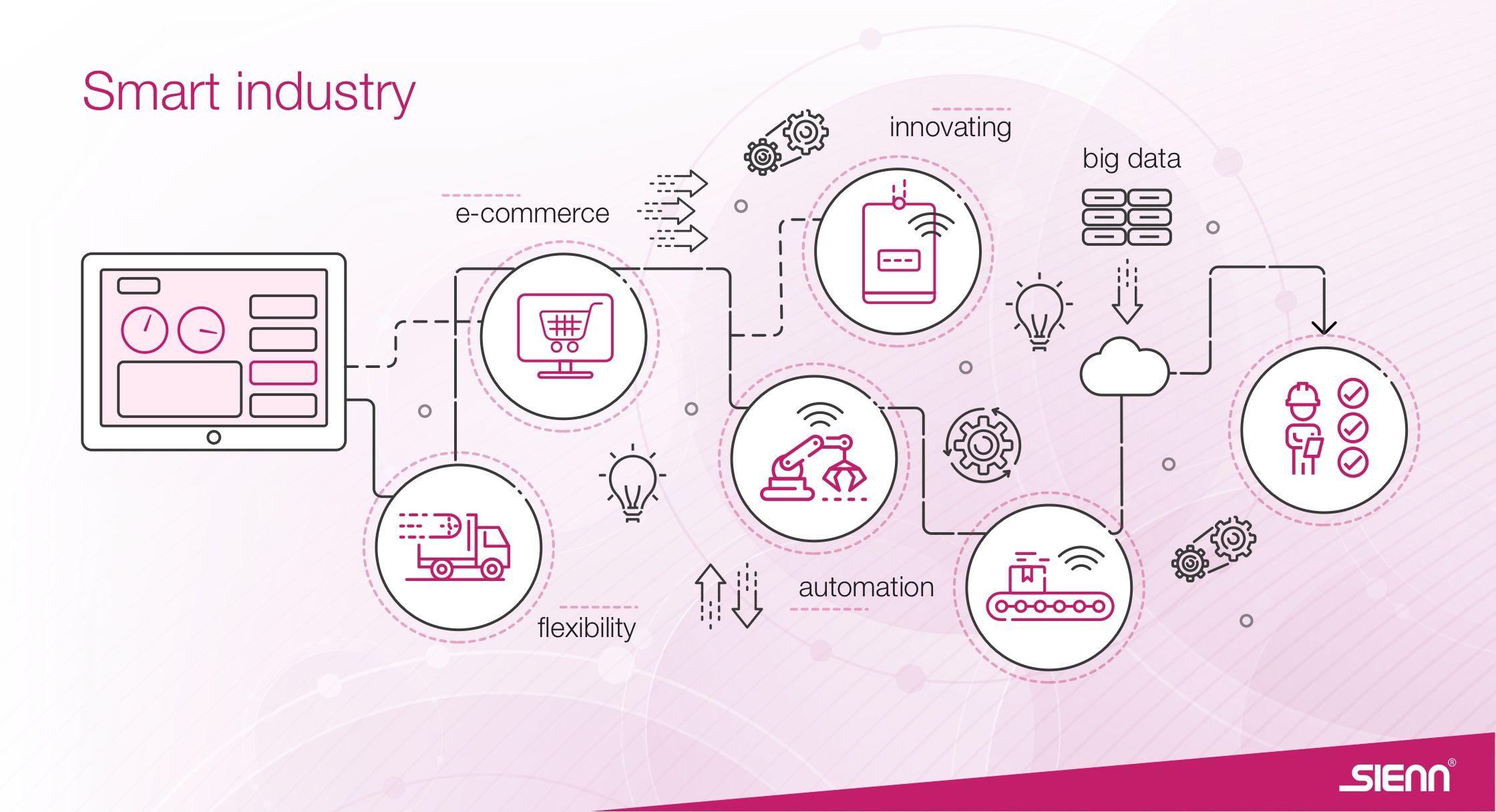

That is why we harness the power of Smart Industry to unlock new efficiencies, empowering you to achieve more with less effort.

Manufacturing companies often know there’s room to improve, but somehow, progress gets stuck. Legacy software from the ’90s is still in use. Excel remains the backbone of operations. Change just feels too risky or too time-consuming.

We understand that change isn’t always easy. It’s also natural to wonder: if we work smarter, does that mean we need fewer people? But Smart Industry isn’t about replacing people, it’s about unlocking potential. Working smarter with what you have creates the space to scale.

Imagine five lumberjacks with hand saws. Give one of them a chainsaw, and he can do the work of five. Give all five a chainsaw, and business can grow.

We see huge potential in mid-sized production companies, think metalworking, machine building, industrial assembly. Many of them already use software, but systems are disconnected, processes are manual, and data is trapped in outdated tools.

Your data is your pot of gold

By unlocking it, you can:

- Use real-time data to drive immediate decisions and keep operations agile

- Seamlessly exchange data across systems for better coordination and fewer silos

- Harness AI to uncover actionable insights that drive smarter strategies

- Automate repetitive tasks to free up time for innovation and boost productivity

When visiting clients, we often spot small inefficiencies that present big opportunities for improvement. For instance, a business receives PDF documents from suppliers, prints and scans them, and then uses OCR to extract the data, even though that same data already exists in the supplier’s system. So why not connect directly? That’s where true efficiency begins.

During such a visit, we take the time to fully understand your processes. We listen to your concerns.

Then, together, we explore the most important questions:

- Where can you save the most time?

- What will bring the greatest return on investment?

- Where can you truly grow with what you already have?

We practice what we preach

We apply the same Smart Industry approach to our own work as well. Instead of isolated, one-off projects, we ensure that our solutions are reusable and scalable, so what works for one company can work for ten, or a hundred.

This gives us a future-proof base to build on, without starting from scratch every time. Using cloud-based solutions and proven tools, we can seamlessly fine-tune along the way and keep improving, so you get a smooth implementation, quick results, and long-term value.

Now it’s your turn. Are you ready to unlock what’s already at your fingertips?